Batch Time Drives Cycle Time

Batch time is one of the major drivers of cycle time in many processes. This quick video provides a simple simulation to demonstrate the effects of batching on cycle time.

Week 42 – Manage Suppliers Better With Operations Science (3 of 3)

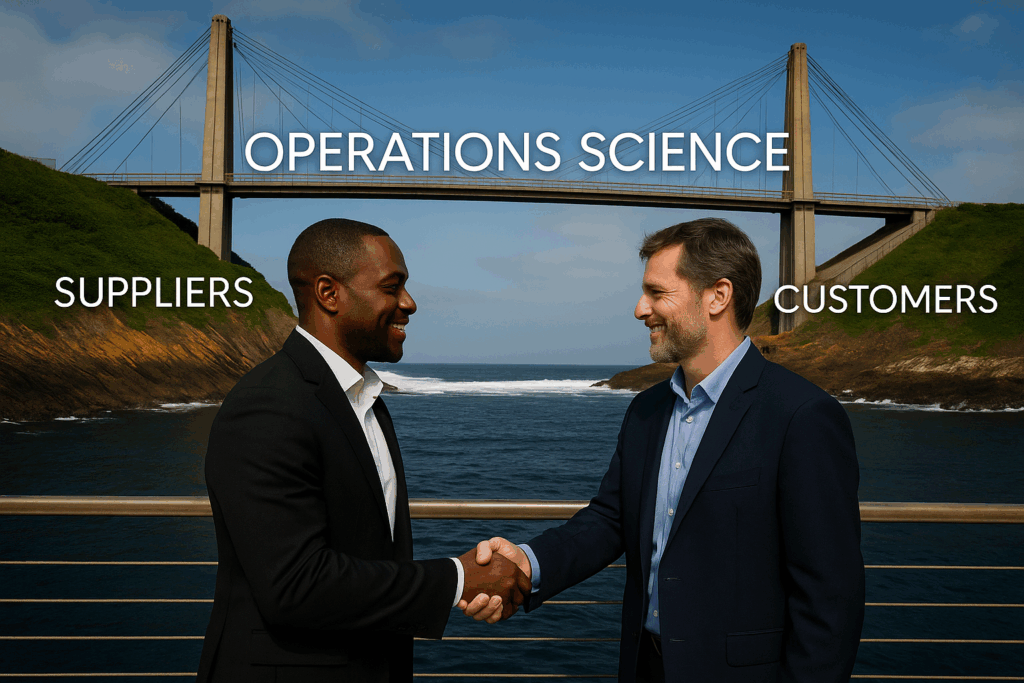

Once a supplier’s supplier’s strengths and weaknesses are understood from operations science-based analysis, supply chain managers can bring price into the conversation and much more easily establish a productive and mutually profitable relationship as we demonstrate.

Week 41 – Manage Suppliers Better With Operations Science (2 of 3)

Just as you would survey the ground to evaluate it as a foundation for a bridge, you should evaluate your suppliers as part of building a relationship. Operations science provides the ability to evaluate suppliers without discussing sensitive cost information.

Week 40 – Manage Suppliers Better With Operations Science (1 of 3)

Learn the secrets of supplier management success using operations science.

Week 39 – New Leaders, Start Fast!

Odds of success for managers stepping into new leadership roles are greatly improved by using operations science concepts to build rapport. See how in this week’s 2-minute video.

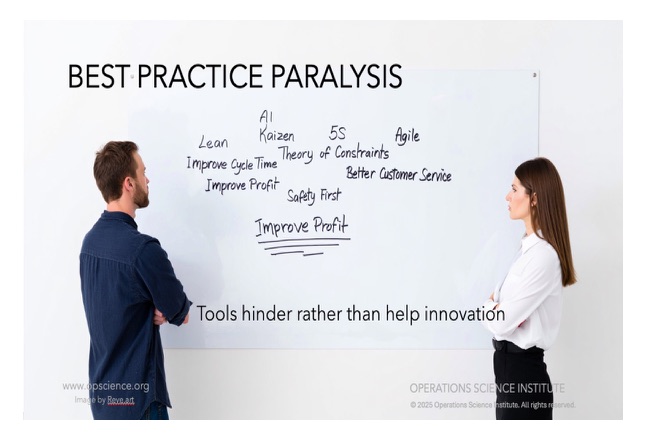

Week 38 – Create Innovation Culture

To create true, sustained innovation, start from first principles in the operations science framework. Tools and best practices come afterwards, they do not make a good foundation for innovation.

Week 37 – Sustain Success, Controls Part 2

Too often people confuse reporting with control. Here we list actual controls that will provide predictable results.

Week 36 – Sustain Success With Control

Good strategy and tactics can be wasted if proper control is not used effectively. Find out how to establish reliable control.

Week 35 – Strategy to Action: Tactics

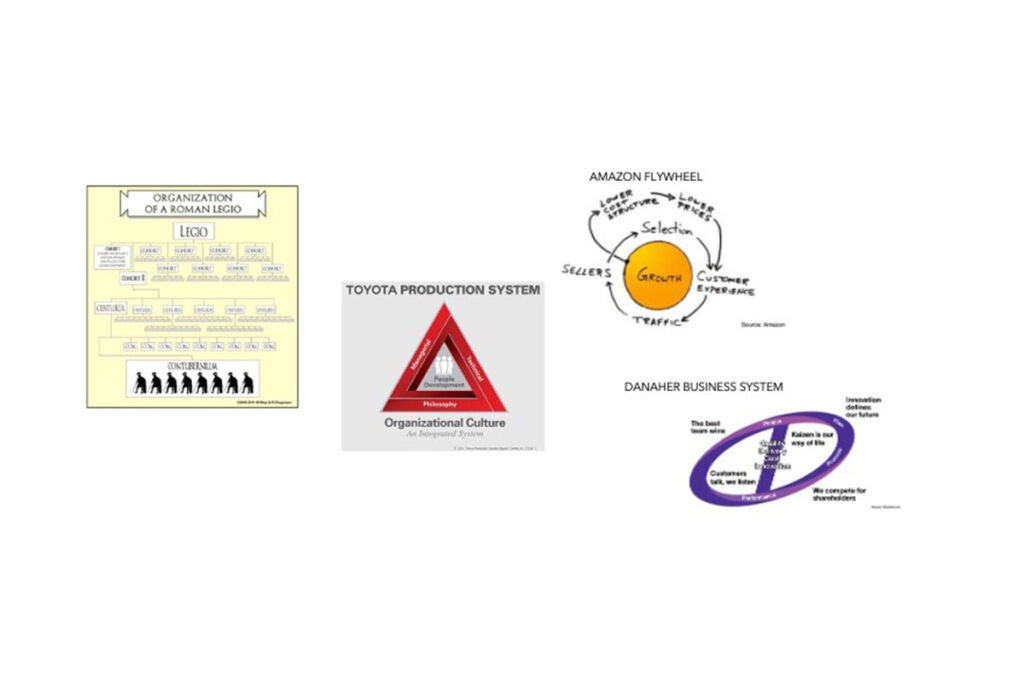

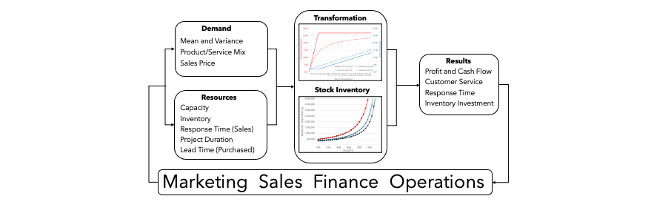

Strategy without action is daydreaming. We describe the business system framework and tactics needed to achieve successful results repeatedly and sustainably.

Week 34 – Make Strategy Work

The laws and concepts of operations science are like an objective third party referee passing judgment on what strategies are or are not feasible. Operations science doesn’t care if you believe in it or not. It dictates outcomes either way.