Redefine Operations Excellence for Improved Customer Service and Efficiency

Operations Science is the study of transformation of resources

to create and distribute goods and services.

to create and distribute goods and services.

Operations science provides a practical, science-based approach to optimize systems and processes. It helps people to more effectively use what they already know and adds new insights, so they can make and sustain powerful improvements themselves.

Operations science strengthens Lean or other continuous improvement programs, and it makes those programs better. Those programs are incomplete without a foundation of operations science. No need to throw out existing efforts. Operations science also improves the productivity of an organization’s existing technology such as ERP, Digital, or Artificial Intelligence.

Operations Science is the discipline that allows AI to be used safely, effectively, and responsibly in operations. AI is a tool; operations science provides the insight and judgement necessary to effectively apply AI.

Operations Science focuses on the interaction between demand and transformation and the variability associated with either or both. Operations Science describes the set of buffers (inventory, capacity, and time) required to synchronize demand with transformation.

What is different about Operations Science?

Everyone in every organization’s operations works with the elements of demand, transformation, variability, capacity, and time. Inventory is also a basic operations element but physical finished goods or raw material inventory is not common to all organizations.

What is different about operations science is that it provides a general description of the relationships between all these elements in a universal framework that can be easily understood and applied to any organization.

As an example of the universal application of operations science, transformation of resources, or “transformation,” is a general term for activity that occurs in all organizations. For example:

| TRANSFORMATION | |

|---|---|

| Manufacturing | Production, Quality Control, Purchasing, Distribution, Maintenance |

| Construction | Engineering, Procurement, Fabrication, Construction, Commissioning |

| Product Design | Consumer Research, Modeling, Prototyping |

| Healthcare | Triage, Diagnosis, Surgery, Billing | Finance | Reporting, Audit, Analysis, Mergers and Acquistion, Budgeting | Legal | Case and Document Management, Research and Analysis, Billing, Resource Allocation, Marketing |

Another primary difference of operations science is that it is very practical. Complex math is not required though operations science allows for very complex math, e. g. Operations Research, should the situation require it. Also, people don’t have to take operations science on faith. When someone in upper management says we need to cut costs, reduce inventory, work less overtime, hire more people, buy more equipment, do Lean, or Six Sigma, or Agile, or implement AI, or go digital, the list goes on, there are very simple checks that can be performed to determine if the recommended course of action is appropriate for the business. Depending on the level of verification required, the simple checks can be backed up with ever increasing complexity of calculations as needed.

Finally, the practical science-based approach is very valuable in that it unites efforts of groups of people since the science is hard to dispute. As an analogy, it would not be productive for someone to attempt to contribute to a meeting by arguing that the law of gravity is not valid. It is productive when everyone understands the implications of the law of gravity and then works together to determine next steps given those constraints.

Operations Science Summary

In a perfect world, demand and transformation would be perfectly synchronized resulting in 100% on-time delivery, minimal capacity, and shortest possible cycle time. There would be zero raw materials or finished goods inventory since both the supplier and the customer would show up exactly when needed. Perfect synchronization would produce best possible cash flow and highest possible profit.

We do not live in a perfect world; we live in a world full of variability. In the presence of variability, demand and transformation never synchronize perfectly. There is variability in demand, customers might order one of something one time and 20 of the same thing next time. There is variability in transformation, people don’t show up for work, raw materials are delivered late, or machines break down, or all of these occur simultaneously.

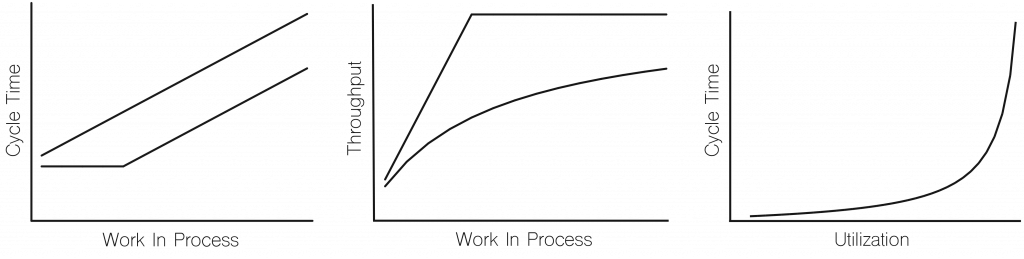

In the real world, variability will be buffered and there are only two buffers—capacity and the time-inventory buffer. For the time-inventory buffer, it is inventory if a product is produced and waits any time before being consumed by demand. If the product is produced any time after demand requires it, demand waits some time to be satisfied. In practice, people deal with capacity, inventory, and time so it is common to speak of three buffers. In any case, variability will be buffered. There are three major relationships vital to successful operations control. These are illustrated below.

The key for successful management is to determine the amount of variability, inventory, time, and capacity that best meets an organization’ goals. To accomplish this determination requires an understanding of the relationships between the basic operations science elements. That these relationships are not widely understood is quite easy to demonstrate, and remedy, for nearly all organizations.

Contact us now and get started. Click here to create a free account and access valuable learning resources.

How Will You Succeed?