Week 52 – Clarity to Lead from Strategy Through Execution

Just as an athlete overcomes powerful opponents, organizations can defeat the hidden forces of waste, stress, and uncertainty by understanding operations science and using its laws to improve flow, resilience, and financial performance.

Week 51 – A Foundation for Successful Leadership

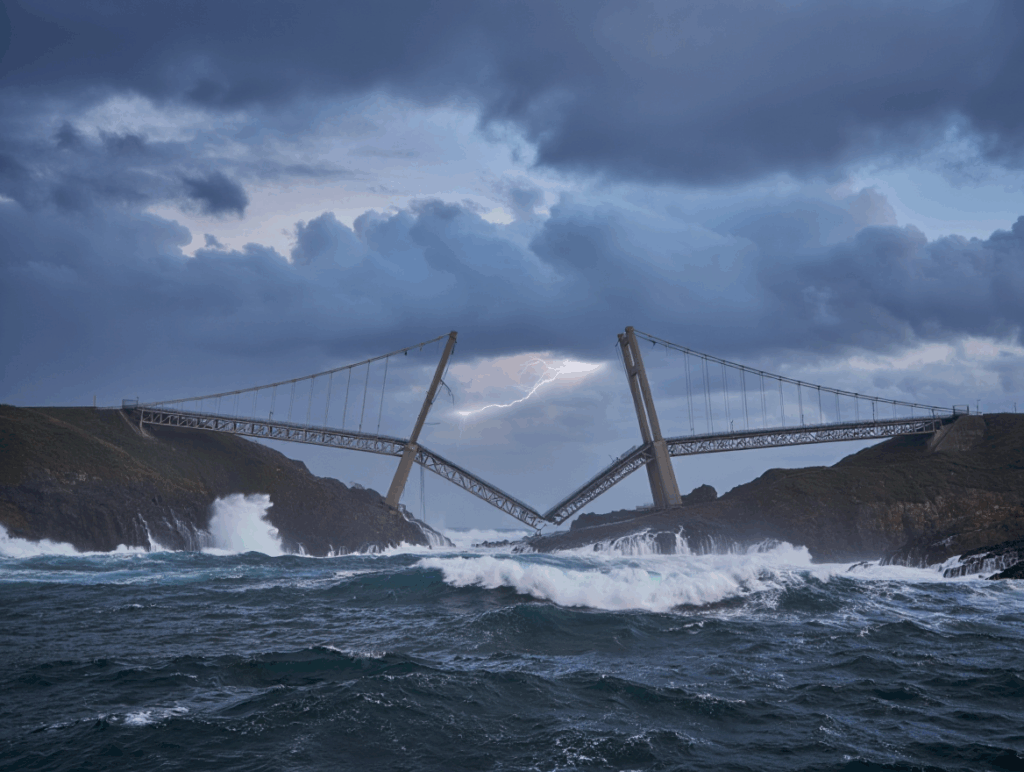

Leadership efforts are greatly weakened without an organization’s or team’s embrace of operations science. Should you try to build a bridge without understanding engineering science? That is doubtful at best. Similar chances of success occur in operations and businesses without understanding operations science.

Week 50 – Designing Resilient Operations

Everyone want their operations or project to be resilient. Very few know how to design resilience into their operations. This week we explore resilience in operations and the traits of resilient operations.

Week 49 – Science Improves Focus and Accelerates Success

Every system — factory, lab, hospital, airline, project — follows natural laws. The leaders who understand those laws lead with clarity instead of chaos. “Working better” is not about working harder — it’s about working scientifically. This week describes operations science fundamentals required for working better and their effect on teams’ efforts for improved performance.

Week 48 – Building Resilience in a Turbulent World

Listen to powerful insights from Sanjay Huprikar, Chief Global Officer, of the Global Electronics Association. Learn how leadership builds resilience in a turbulent, $6 trillion electronics industry. Discover how to drive smarter, faster, and more resilient operations.

Week 47 – From Grounded to Greatness, The Delta TechOps Story

Operations science played a key role in helping Delta TechOps rebuild from the severe disruption of Covid and, at the same time, embark on an ambitious growth plan for its maintenance, repair, and overhaul business. We summarize the compelling podcast of Mike McBride, VP of Engines and Components, and his take on the events. It provides powerful lessons on crisis management in operations.

Week 46 – Mistakes in Annual Planning

There are a couple of common, avoidable mistakes that organizations make when creating their annual operating plans. This 2-minute video describes those mistakes.

Week 45 – Batch Size Optimization

Batch size optimization decisions must consider capacity utilization, not only setup cost and inventory cost.

Week 44 – Operations Science Essentials

No manager or executive should be put in charge of operations without understanding these fundamental relationships.

Week 43 – Operations Science Supercharges Any “Go to Gemba” Effort

Operations is not a black box. You should start any gemba journey with an operations science map to guide you quickly and efficiently.