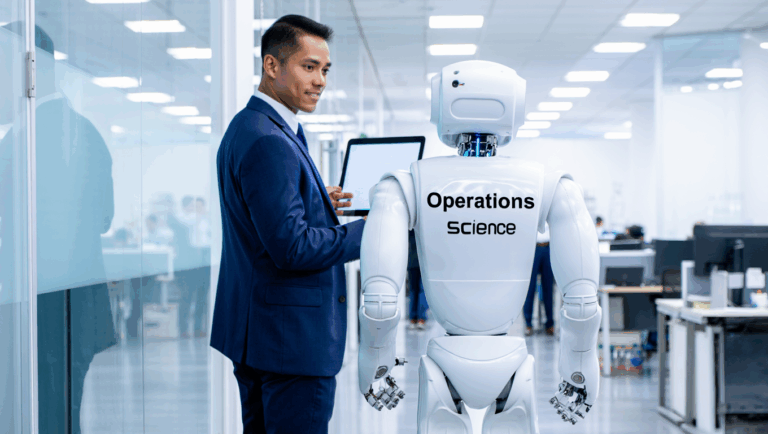

Week 52 – Clarity to Lead from Strategy Through Execution

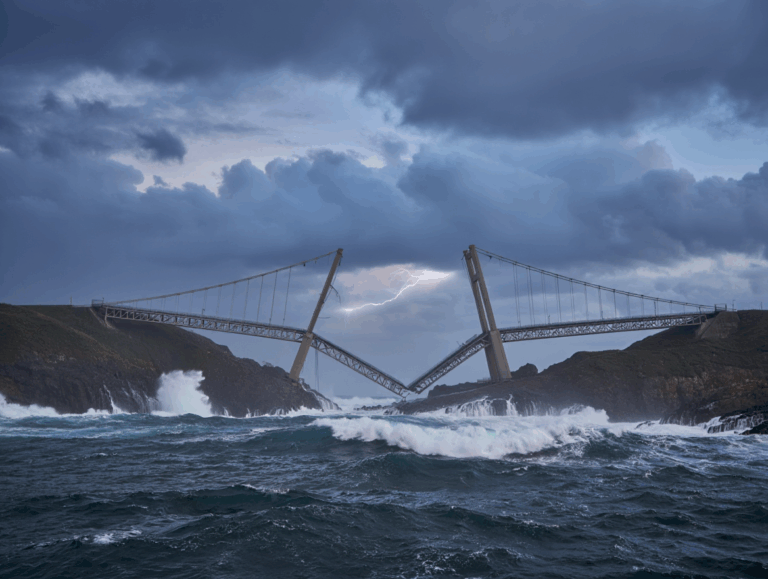

Just as an athlete overcomes powerful opponents, organizations can defeat the hidden forces of waste, stress, and uncertainty by understanding operations science and using its laws to improve flow, resilience, and financial performance.